Salts & Dampness

Salts are present in many building materials but not usually at concentrations where they are noticeable or cause us any problems.

It is therefore easy to see why salts are often overlooked by many or disregarded if a damp problem is encountered.

The presence of salts at a concentration that makes them noticeable usually involves the movement of moisture. This is because salts are water soluble and will mobilise in damp materials. In locations where dampness evapourates these salts will be left behind as the salt cannot evaporate. This process over a period of time will lead to an accumulation of salt.

There are commonly 2 different forms of salts that are associated with dampness:-

Efflorescent Salts

Efflorescent salts are visibly identifiable by their fine white powdery appearance. Sometimes they can appear fluffy or foamy. The occurrence of efflorescent salting is referred to as efflorescence.

Efflorescence is often encountered where dampness has been or is a problem. Problems experienced are usually due to the visible effects of the salts. Being white in colour they stand out and stain masonry which can be unsightly. They may also damage to decorations by creating blisters to paint and plaster and in some cases, they can react with paint discolouring freshly painted surfaces.

Prevention

To prevent efflorescence it is important to stop the migration of dampness that is causing it. Surfaces should then be encouraged to dry. This can take a long time depending on the amount of dampness and thickness of the wall. Once dry salting can be brushed from the wall with a stiff brush. If salt staining is left behind then the use of a dissolving acid treatment will often remove this.

It is common for persistent salting to occur on some masonry walls caused by repeated wetting and drying of the structure by rainwater. This can often be overcome by protecting the structure with a water-repellent coating. This will stop the wall from absorbing rainwater. It is important that any water repellents used are microporous so as to maintain breathability of the wall and allow moisture vapour to escape.

Hygroscopic Salts

Hygroscopic salts have the ability to attract moisture. These salts are not usually visible, certainly not to the extent of efflorescent salts. This is because they usually remain in a dissolved state in water held within the pores of the substrate. Their presence can sometimes be identified by this salt water in the form of a wet looking stain.

Hygroscopic salts can be damaging to many elements of a building and can cause:-

The accumulation of hygroscopic salts to a concentration that starts to become apparent is often referred to as hygroscopic salt contamination.

What causes it?

Hygroscopic salt contamination can occur due to a number of reasons such as:-

How to Identify Hygroscopic Salt Damp

Sometimes it can be as simple as just looking at the location of the problem or knowing a little history about the building as certain materials and locations of a building are commonly associated with hygroscopic salt contamination.

Laboratory tests can also be undertaken. These will require samples of masonry or plaster to be taken.

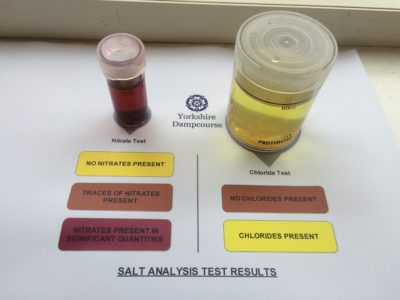

A basic qualitative test can be undertaken on site for the presence of chlorides and nitrates – hygroscopic salts that are commonly associated with rising damp. This is particularly useful if a prompt result is required.

Prevention

If a structure is contaminated with hygroscopic salts then there is very little you can do about it. The contamination is part of the structure and it can only be removed if the contaminated material is removed. This is not very practical if structural components are contaminated.

However, it can be managed. Management requires the contaminated material to be isolated. For example, a separation layer may be inserted between the contaminated material and the new material. This is the purpose of replastering as part of a rising damp treatment.

Isolation is a very common repair. Methods include:-

Method 1

Isolation Membranes

The application of a physical membrane is often the first choice as an isolation barrier. These membranes are made from high-density polyethylene (HDPE). HDPE membranes are high-quality plastic membranes that will provide a completely impenetrable barrier against salt contaminants. These are mechanically fixed to masonry walls and can be loose laid over solid floors. A variety of finishes can then be applied over them such as plasterboard linings.

Method 2

Tanking Coatings

A common approach to managing hygroscopic salt contamination is to use a cementitious tanking. These work by blocking the movement of the moisture that contains the salts. These are then covered using a render and plaster skim coat.

Method 3

Salt Resistant Plaster Systems

Salt resistant plaster systems can be cement or lime based. They can be supplied as a blended batched mix or can be self-made using a specific blend of sand, cement and additives. They are mixed with water and trowel applied. These systems are typically used for rising damp treatment only.

Method 4

Salt Resistant Coatings

An innovative system has recently become available that allows the used of plasterboard linings without the need for a physical membrane. Our supplier Safeguard Europe has developed this system known as the ‘Dryzone Express Replastering System’. This system uses a salt/water resisting cream primer to be applied to exposed masonry walls prior to the adhesion of plasterboards using a special grab adhesive. This system is suitable as part of rising damp treatment only.